IDC Alternatives Composites

La boutique

en fibres carbone haute résistance ?

Les plaques proposées sont en stock.

L’envoi est effectué dans un maximum de 72 heures ouvrés après la commande.

Pour tout autre format, épaisseur, finition ou usinage,

nous sommes à votre disposition pour réaliser des devis selon vos plans.

En complément du carbone, nous découpons également à la demande du DIBOND ou tout panneau composite aluminum.

L’entreprise

Spécialisée dans les matériaux composites hautes performances, IDC Alternatives Composites propose études et réalisations de pièces en carbone et de panneaux sandwichs pour les donneurs d’ordre nationaux des secteurs de l’aéronautique, du bâtiment, du sport ou du modélisme.

Sa structure équilibrée lui permet d’être très réactive sur les projets comme sur les demandes de prototypes et son équipement spécialisé fait d’IDC l’un des rares ateliers pouvant travailler des plaques de carbone de grand format (jusqu’à 4 x 2 mètres).

Créée en 2011 par Pascal Le Loirec et Dominique Le Mahier, deux experts du composites, IDC Alternatives Composites est installé au coeur d’une plate-forme de 6000 m2 au total et bénéficie de matériel de toute nouvelle génération, d’une zone logistique et expédition commune et d’un pôle qualité mutualisé.

Conseil et gestion de projet

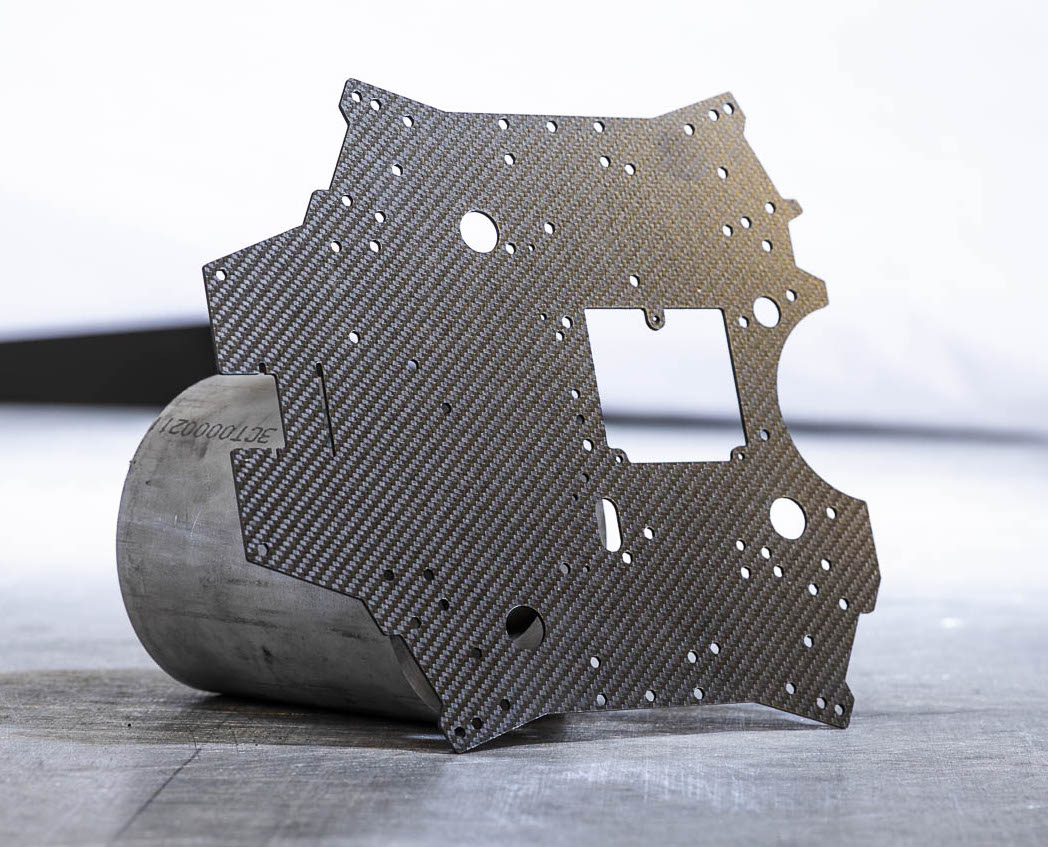

Nous vous assistons et conseillons dans la finalisation de vos projets. Nos logiciels de CFAO permettent de réaliser des pièces en 3D, des plans de définition et d’éditer des programmes complets pour l’usinage. Ces logiciels supportent les échanges avec d’autres sources par l’intermédiaire de fichiers DXF, IGES…

Le parc machines

Le parc machines dédié à la fabrication de matériaux composites intègre des presses pour moyens et grands formats, fraiseuses haute fréquence pour des réalisations allant du prototype unitaire aux moyennes séries.

Presse hydraulique #1 moyen format

- Dimension maxi : 1300 mm x 3000 mm

- Pression 3kg/cm2 sur 100% de la surface

- Température 120°C

- Pilotage et régulation de la température et pression par automate programmable

- Récupération des données de cuisson par informatique (suivi qualité)

Presse hydraulique #2 moyen format

- Dimension maxi : 1300 mm x 2500 mm

- Pression 7,3kg/cm2 sur 100% de la surface

- Température 200°C

- Pilotage et régulation de la température et pression par automate programmable

- Récupération des données de cuisson par informatique (suivi qualité)

Presse chauffante multiplateaux

- Dimension maxi : 1600 mm x 3000 mm

- Pression 3kg/cm2 sur 100% de la surface

- Température 200°C

- Pilotage et régulation de la température et pression par automate programmable

- Récupération des données de cuisson par informatique (suivi qualité)

Etuve

– Réalisation de pièce moulée sous vide

2 étuves :

Etuve N°1 : Dimensions 2200 x 1250 x 1000

Etuve n°2 : Dimensions 1000 x 1350 x 970 mm

Température maxi 250°C

Presse hydraulique #4 Grand format

- Dimension maxi : 4000 mm x 2000 mm

- Pression 5kg/cm2 sur 100% de la surface

- Température 150°C

- Récupération des données de cuisson par informatique (suivi qualité)

Fraiseuse #1 - SBC Automation

Fraiseuse 3 axes exclusivement dédiée à l’usinage des matériaux composites

- Electrobroche 8kw – 36 000 tr/mn.

- Axe X : 3100 mm / Axe Y : 2100 mm / Axe Z : 400 mm.

- Changeur 11 outils avec mesure laser longueur et rayon.

Fraiseuse #2

Zone de stockage de 600m2

Salle de réunion

Salle de drapage

Zone de production de 800 m2

Salle d'Infusion

Vestiaire

Vestiaire

Notre Savoir-Faire

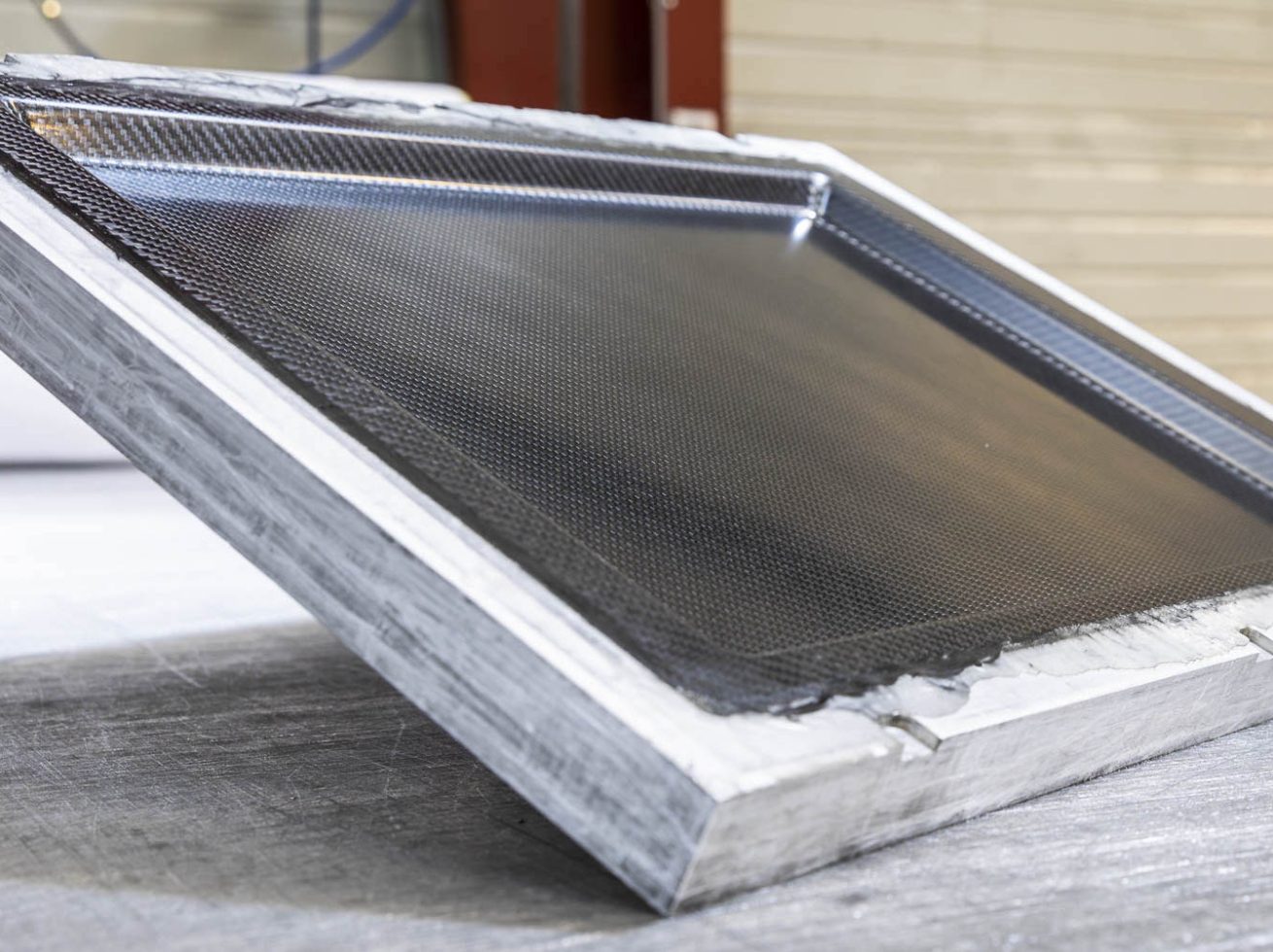

Fabrication de panneaux

L’utilisation des panneaux et structures sandwichs permet, face à des applications réalisées habituellement dans des matériaux traditionnels, de réduire le coût d’exploitation grâce à une diminution notable du poids, conséquence logique de l’amélioration des performances mécaniques.

Principe : 2 peaux résistantes collées de part et d’autre d’une âme de faible densité.

Photo : Panneaux en nid d'abeille

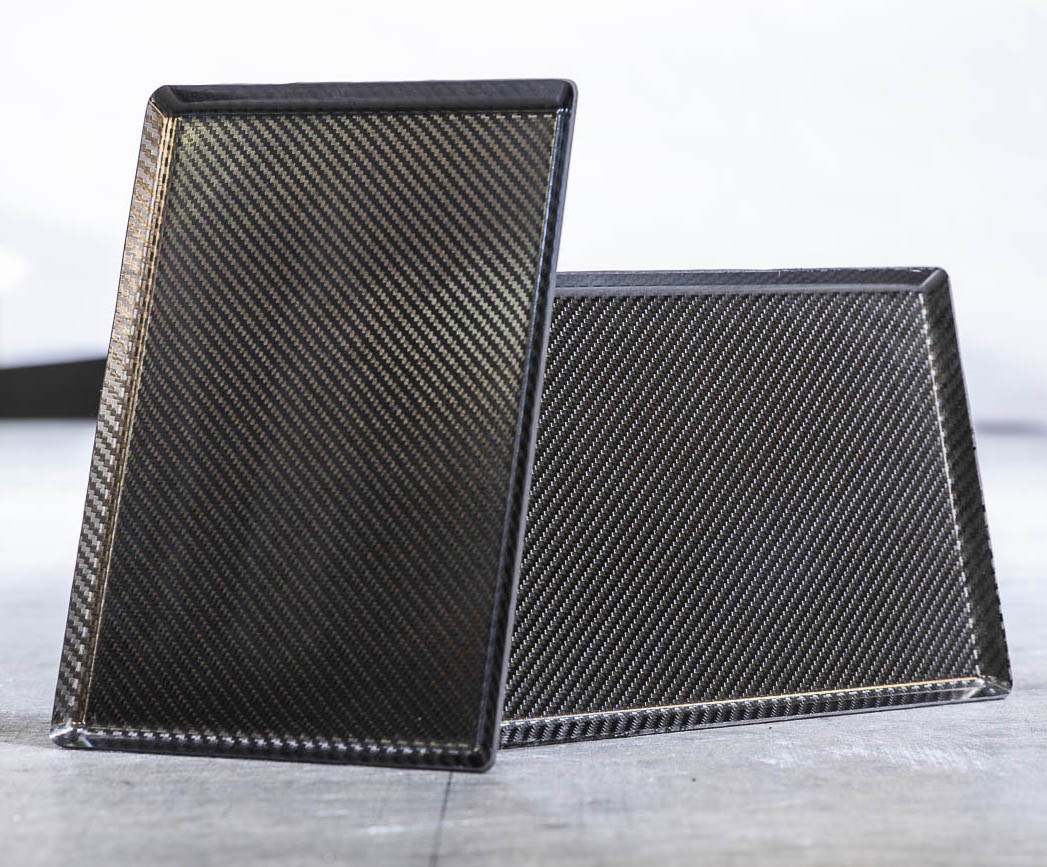

Plaque de carbone

Dimensions jusqu’à 4000 x 2000 mm

Epaisseur : de 0,4 mm à plus de 10 mm

Fabrication de plaques carbone sur commande

A la demande à vos dimensions

Usinage de toutes formes, suivant vos plans.

Découpe et usinage de plaques

Il existe différentes couleurs de carbone pour des réalisations particulières.

Tissus carbone

Exemples de réalisations

Nos Partenaires

On parle de nous

Contactez-nous

Coordonnées

IDC Alternatives Composites

8 rue Armand Busquet

14400 Bayeux

02 31 51 67 03

Communication

Corinne Cauville

c.cauville@idcomposites.fr

Suivez-nous

Dominique Le Mahier

d.lemahier@idcomposites.fr

Pascal Le Loirec

p.leloirec@idcomposites.fr